Produktbeskrivelse

Minimal part costs

High machine dynamics, even for complex contours, due to powerful drives and dynamic axis motions.

The best results without compromise

BrightLine fiber facilitates excellent part quality and seamless part removal.

Highspeed and Highspeed Eco

A new nozzle design reduces nitrogen consumption by up to 70% – for double the sheet throughput.

Full power of the laser on the sheet metal

Utilize the full power of the laser: our machines are designed so that every single kW hits the sheet. This means that not only do you achieve high feed rates, but you are also able to process the workpiece productively.

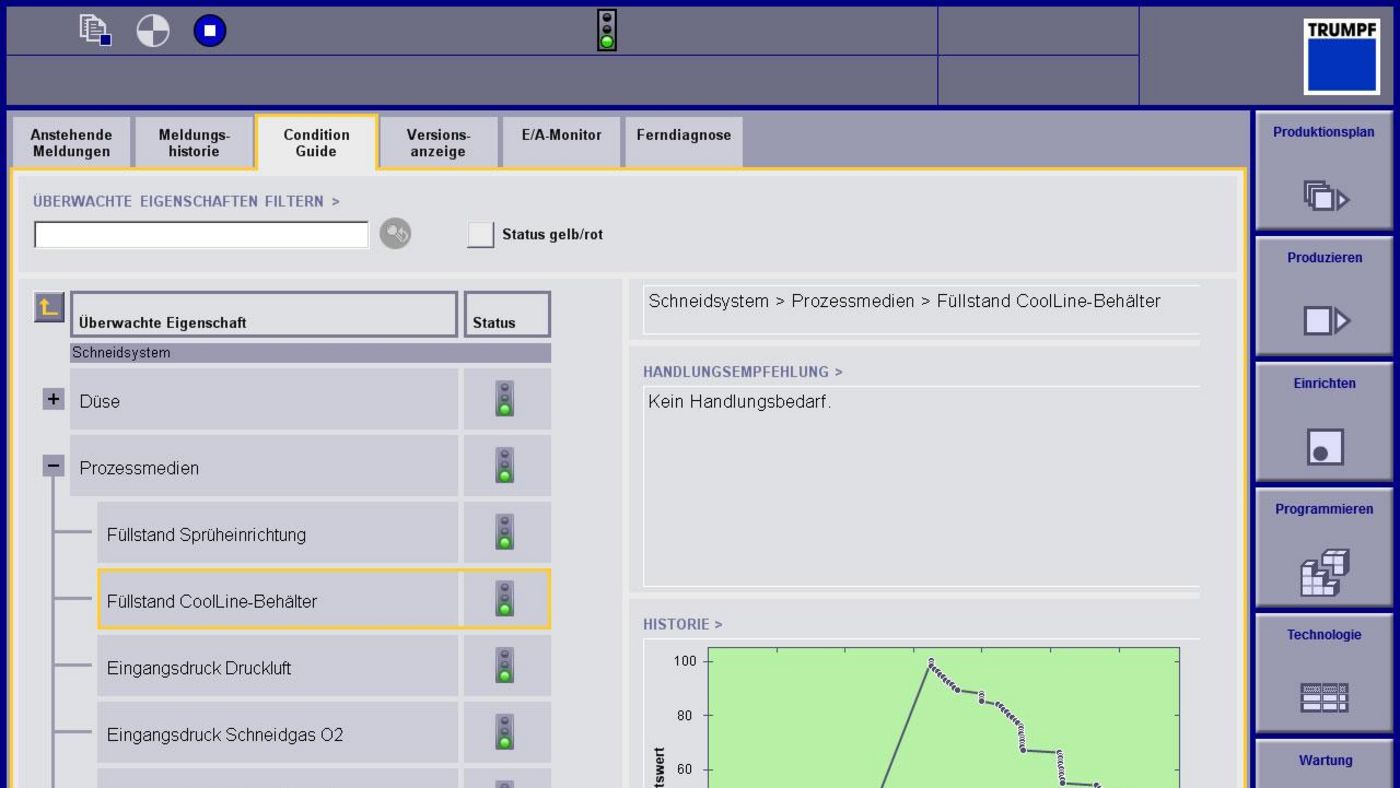

Perfect nozzle quality

Smart nozzle automation ensures a high quality of nozzle – even in fully automatic operation. The nozzle changer can be pulled out while the machine is cutting and be set up parallel to production.

Simple operation

The multi-award-winning Touchpoint HMI enables you to operate the machine much faster and more intuitively, with the same excellent performance.

Cut oversized sheets

Quickly and easily machine sheet metal measuring 6 x 2 m.

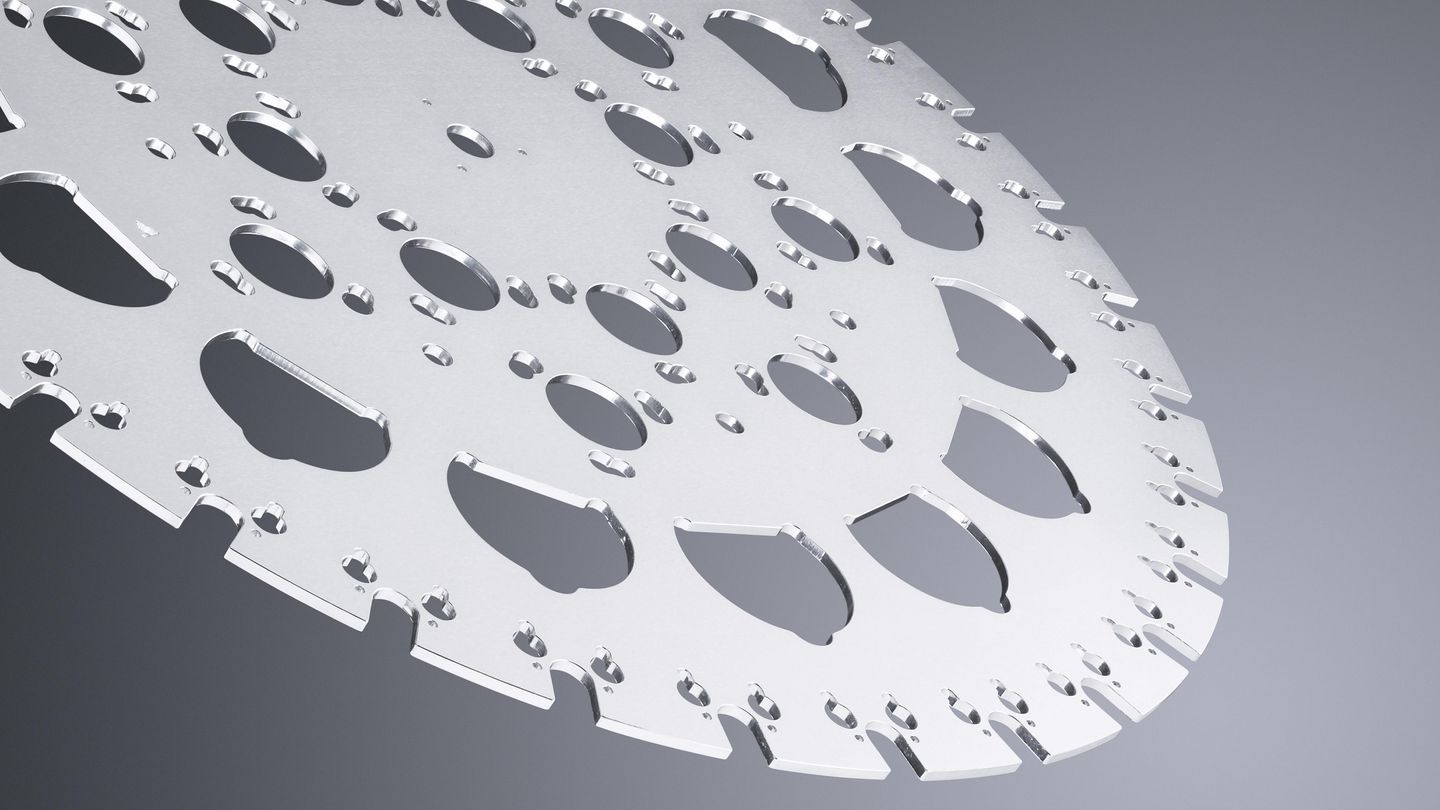

Intricate cutting even in thick mild steel

With the CoolLine function, you can even create fine contours in thick mild steel

Utilize the full power of the laser

Utilize the full power of the laser

Imagine that you are driving a car with 400 hp – but no matter how much you step on the gas, your car just cannot translate the engine’s capacity onto the road. Our machines are designed so that the full power of the laser really hits the sheet metal to prevent you from having that problem with laser cutting. The complete package of machine, laser power and functions is decisive for quality and productivity. Perfectly coordinated: only available with TRUMPF. Fully utilize laser power of up to 12kW on the workpiece – this gives you the best results even with difficult parts.

Automation

Loading

Your entry into automation: The

LoadMaster enables the automatic loading of your machine with raw sheets.

Loading and unloading

The

LiftMaster Compact loads and unloads your machine completely automatically. The LiftMaster Linear Basic increases the utilization of up to two machines

Loading and unloading / Part sorting

The automation solution,

LiftMaster, covers a broad range of automation functions. It loads and unloads, but is also suitable for pallet handling or part removal. The LiftMaster Sort also separates finished parts from the scrap skeleton. LiftMaster Store and LiftMaster Store Linear connect your system directly to the store. The SortMaster automatically sorts finished parts.

Auxiliary pallet operation

The

PalletMaster Tower enables flexible material handling around the clock. It combines the automatic changing of pallets with compact storage technology.

Storage system

With the storage systems of the

TruStore Series 1000 and

TruStore Series 3000 you can organize your material handling according to your requirements.

Utilize the full power of the laser

Utilize the full power of the laser