Produktbeskrivelse

Carrying capacity of 132 lbs. with the BendMaster (60)

Carrying capacity of 132 lbs. with the BendMaster (60)

Sheet sensors detect the precise position and guarantee that components are recorded reliably. An additional centering station is no longer necessary

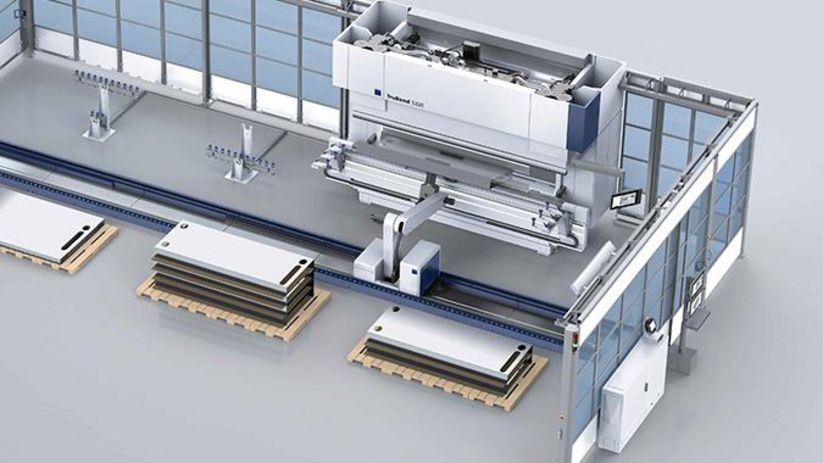

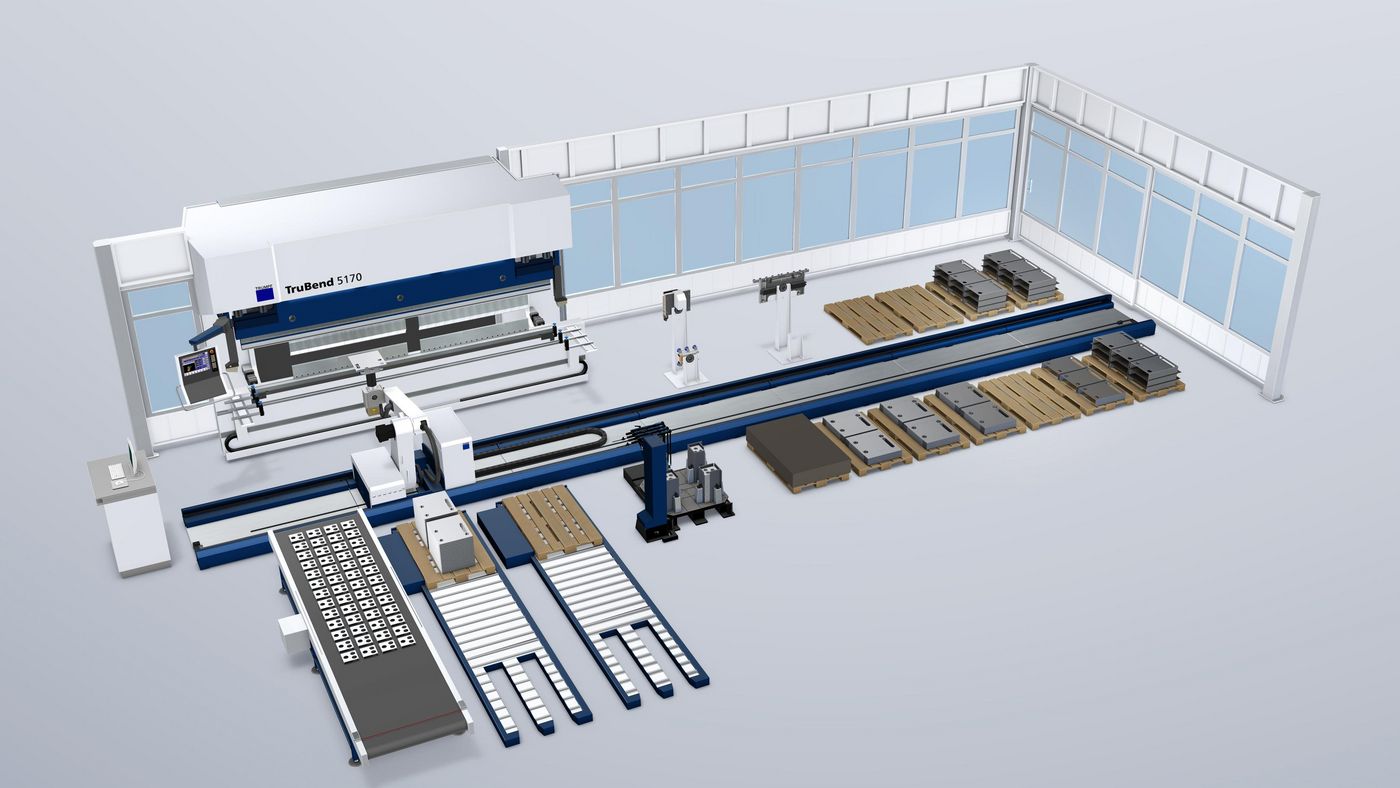

The TruBend Cell 5000 is the perfect solution for those who value productive and flexible automation, for the widest possible range of parts as well as a consistently high part quality. The automatic bending cell now enables you to process your components even more efficiently. Users select the bending machine and BendMaster according to their individual range of components. You also have maximum freedom in the design of the material flow using conveyor belts and pallet conveyors.

Carrying capacity of 132 lbs. with the BendMaster (60)

Carrying capacity of 132 lbs. with the BendMaster (60)

Sheet sensors detect the precise position and guarantee that components are recorded reliably. An additional centering station is no longer necessary

The console enables autonomous gripper changes as well as automatic processing of various orders, all without the need for manual intervention.

The conveyor belt removes small parts that cannot be stacked.

The pallet conveyor loads blanks or unloads finished workpieces without interrupting the bending operation.

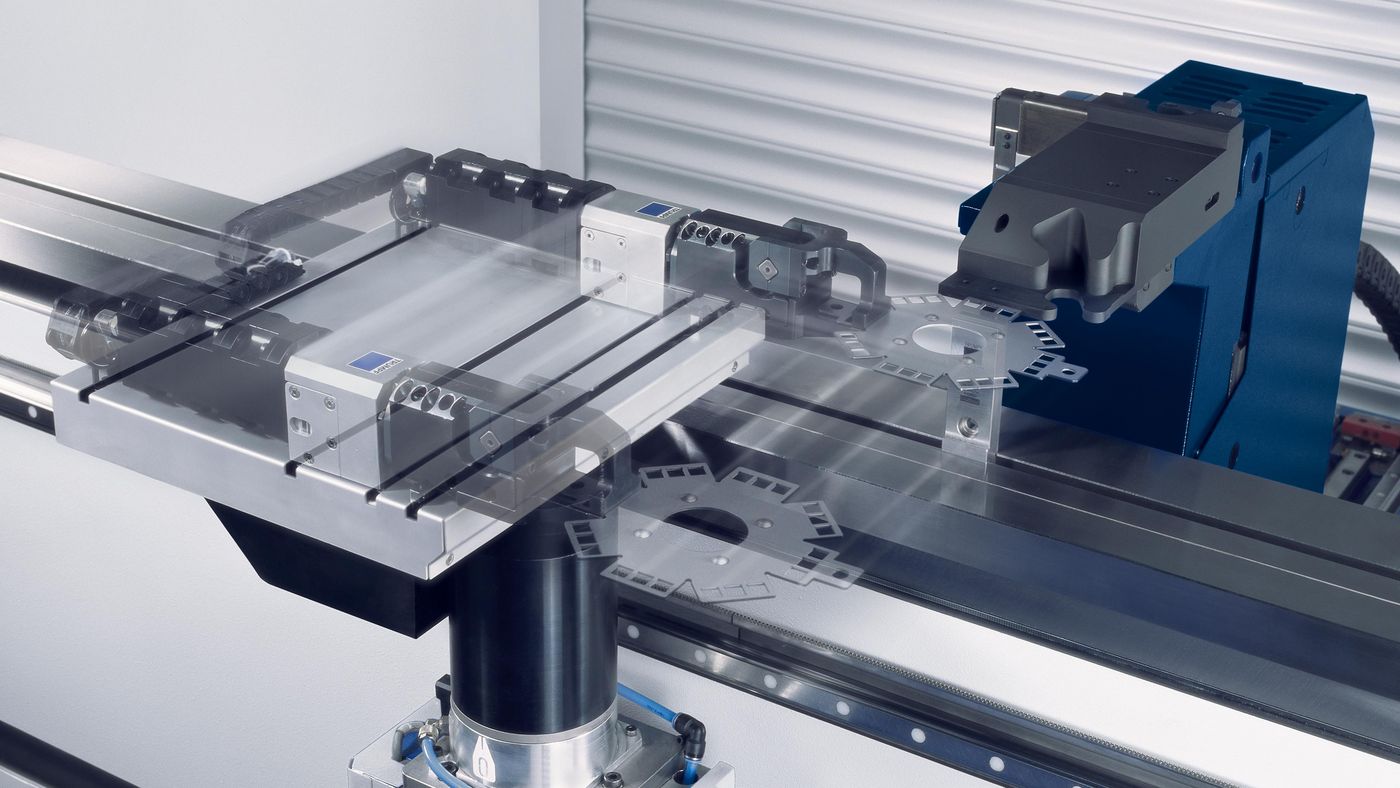

With the ToolMaster automatic tool changer, you can set up the TruBend Cell 5000 automatically for each new program. This represents a priceless benefit, particularly for small lot sizes. You save time and effort.

The sheet removal station can separate and produce up to four component types parallel to production in a single operation.

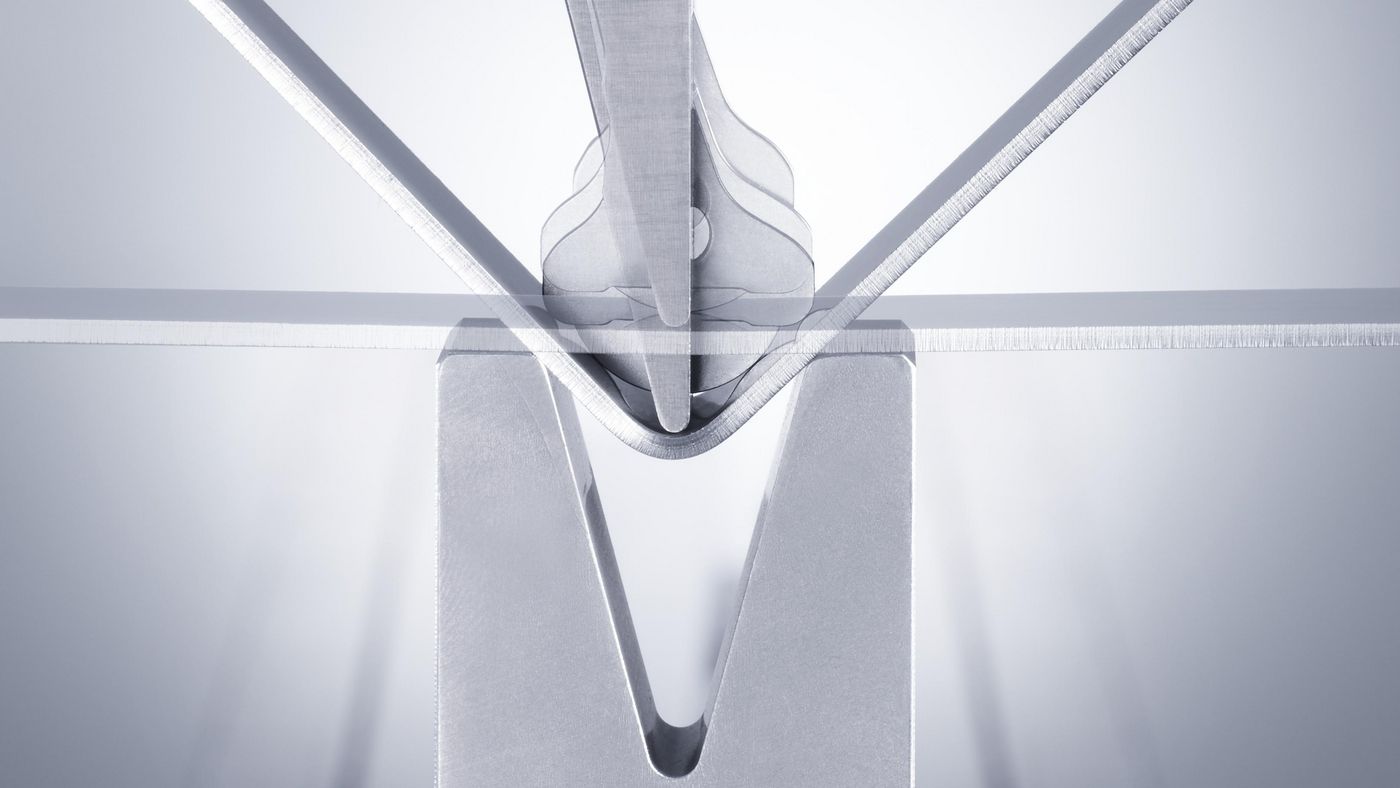

You can achieve consistently precise angles using the tried-and-tested Automatically Controlled Bending angle measuring system – without any manual intervention.

The sensor system on the 4-axis or 6-axis backgauge accurately positions your components.

You can freely select the length of the floor lane. This ensures there is enough space for blanks and finished parts.

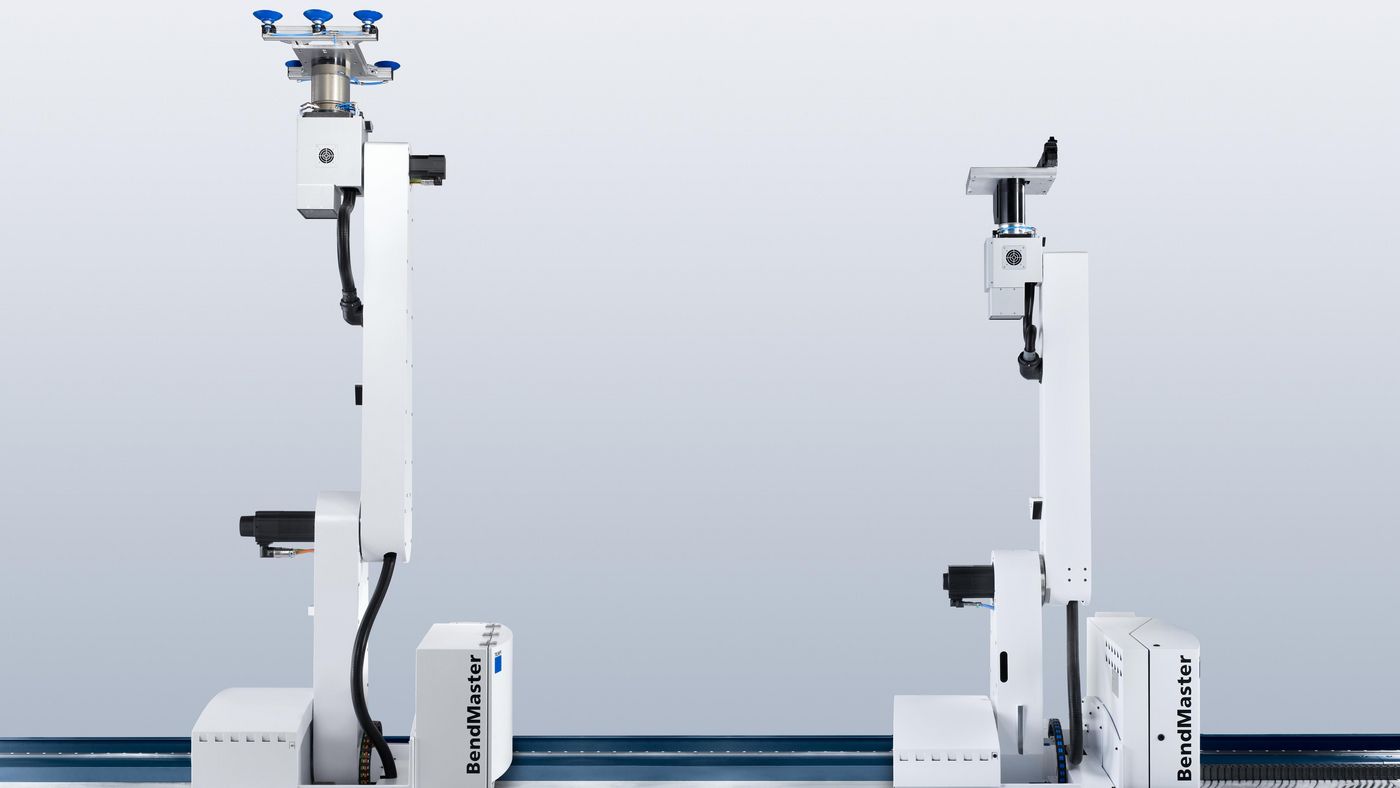

With the BendMaster (60) and BendMaster (150), you always have the right automation solution for every range of parts.

You can choose between more than 150 upper and lower tool types for your personal range. You can order tools individually or as a set.

You can achieve consistently precise angles using the tried-and-tested Automatically Controlled Bending angle measuring system – without any manual intervention.

For specific requirements, TRUMPF will develop your own personal tool solution. To guarantee the quality of your parts, we test the tools in advance with your specific material and create initial sample parts.