LiftMaster Compact

Our best-in-class

The LiftMaster Compact is the fastest and most compact loading and unloading unit in the TRUMPF portfolio. The dynamic and variable automation solution is particularly attractive for fast sheet processing times, regardless of whether with or without storage connection. It requires little space and saves time and money with its short cycle time of 90 seconds.

Storage connections

TruStore Series 1000

Practical compact store

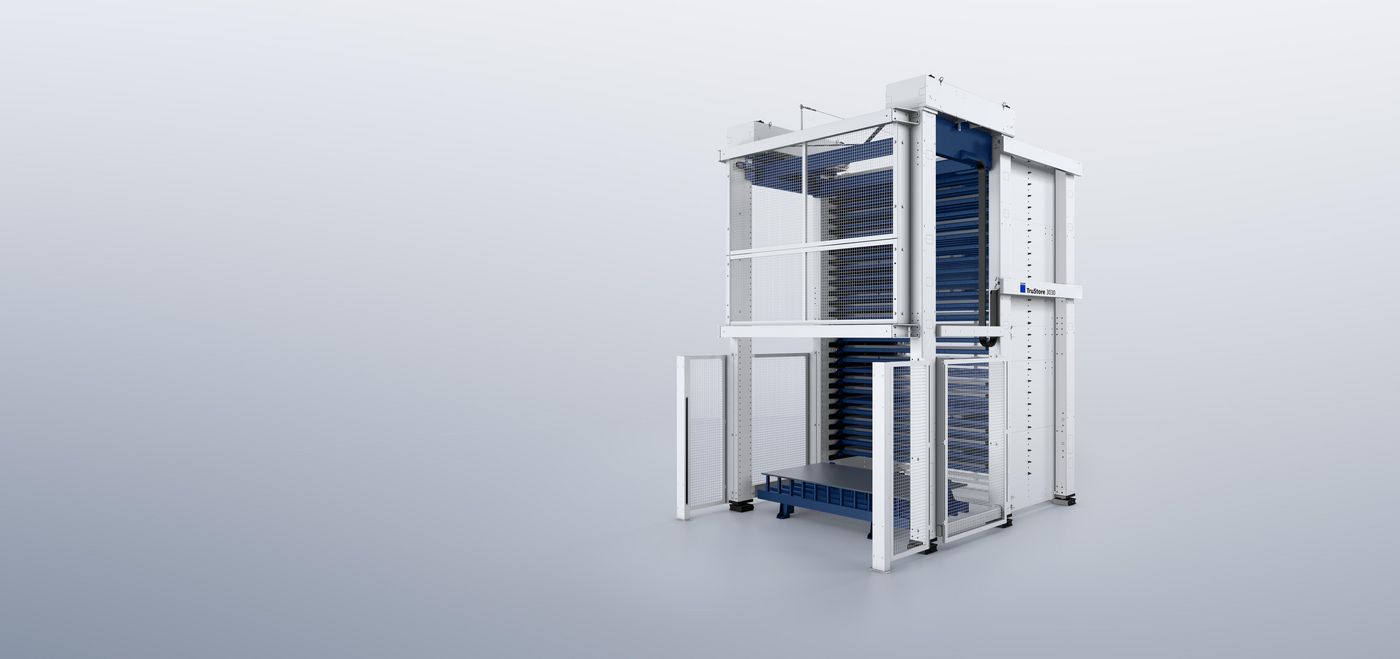

TruStore Series 3000

The most flexible Storage

Equipment

PartMaster

With the PartMaster you can easily remove finished parts and scrap skeletons manually, without problems.

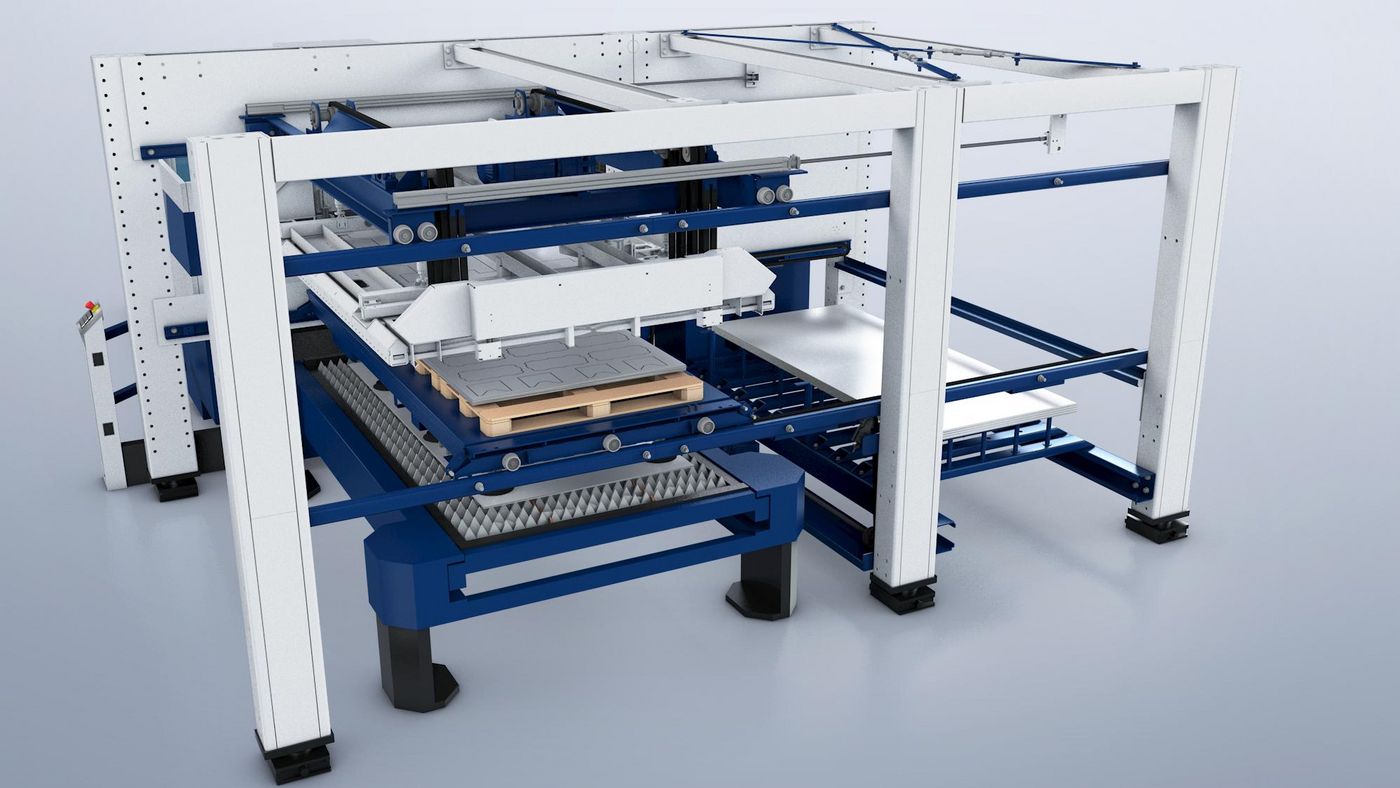

Synchronous loader

The synchronous loader has a suction frame that transports a finished part pallet, onto which the cut sheets are placed. It traverses horizontally between the unprocessed material table and the pallet changer.

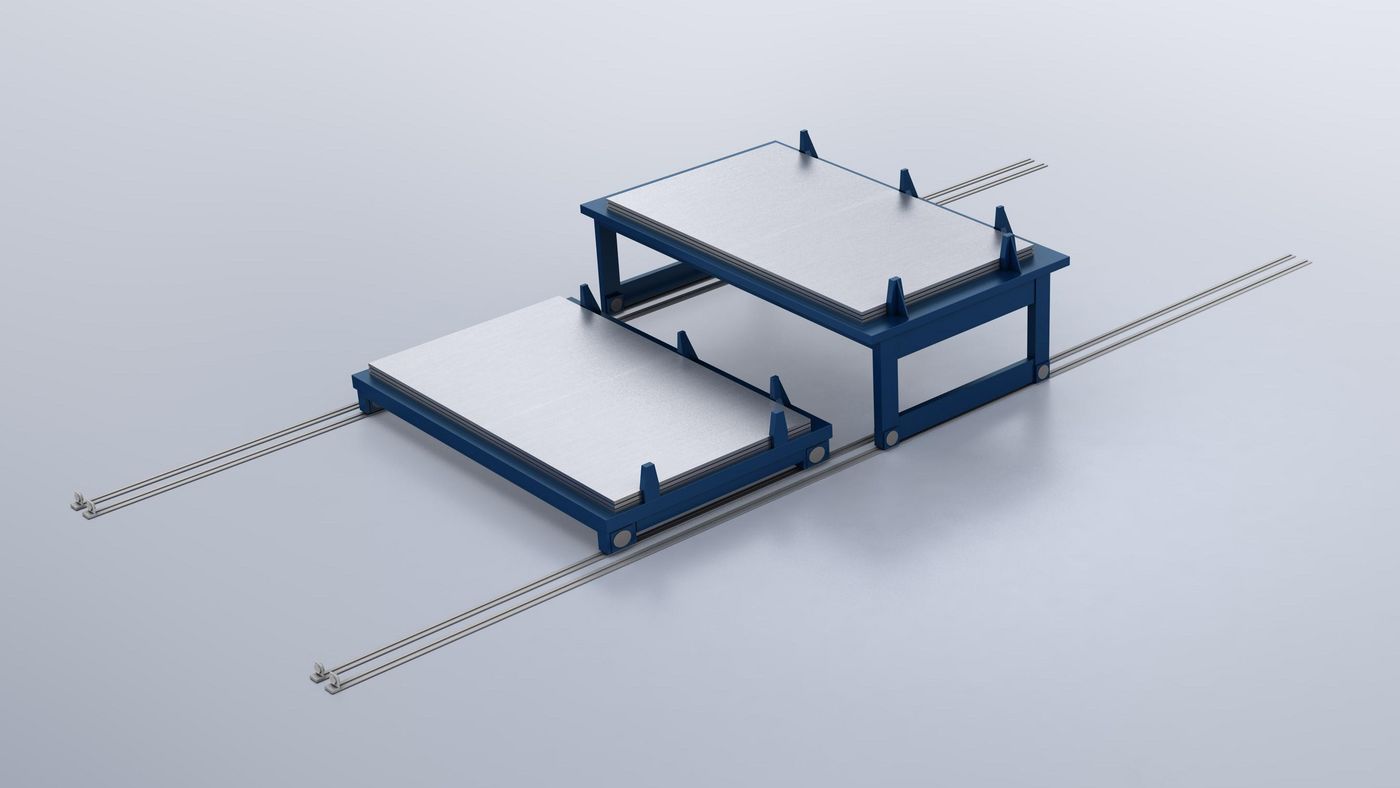

Cart systems

Instead of the standard unprocessed material table you can use loading carts.