SBM-M D2

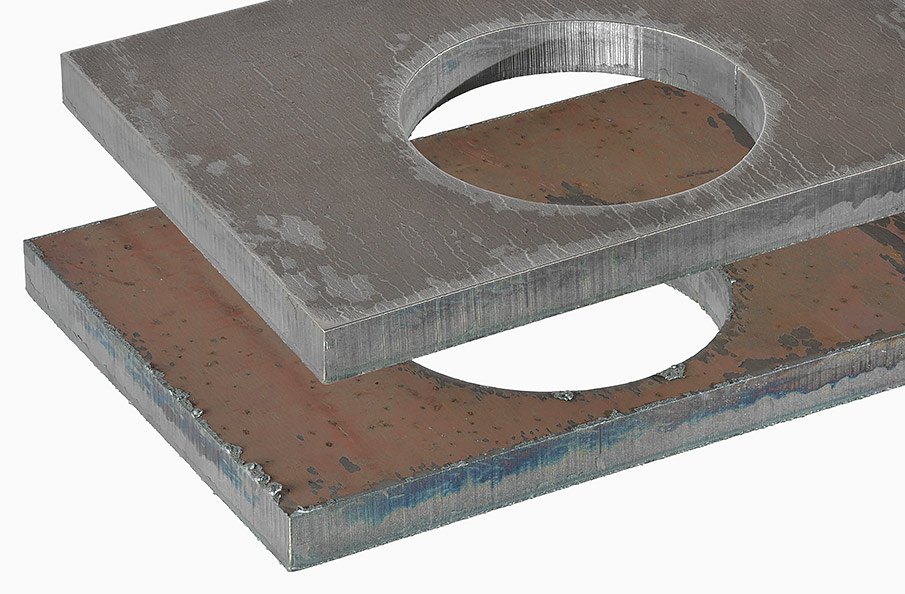

LISSMAC systems for metal processing set benchmarks in innovative sheet metal processing through highly-effective, two-sided removal of slag on plasma and thermal cut workpieces using only one work process. Unlike grinding machines, SBM-M D2s win over customers with more efficient processing work savings of up to 60%. Tool costs are significantly reduced in comparison to expensive machining with abrasives due to mechanical removal of the slag.

- Two-side slag removal of plasma and thermal cut sheets up to 120 mm

- Saving of tool costs incurred by mechanical deslagging –no time-consuming and expensive grinding

- Two-side slag removal saves the time intensive turning of the often very heavy workpieces or machining of parts twice

- Up to 60 % work time savings compared to one-side processing machines

- Modular and compact in modern machine design – smaller footprint

- Dry operation

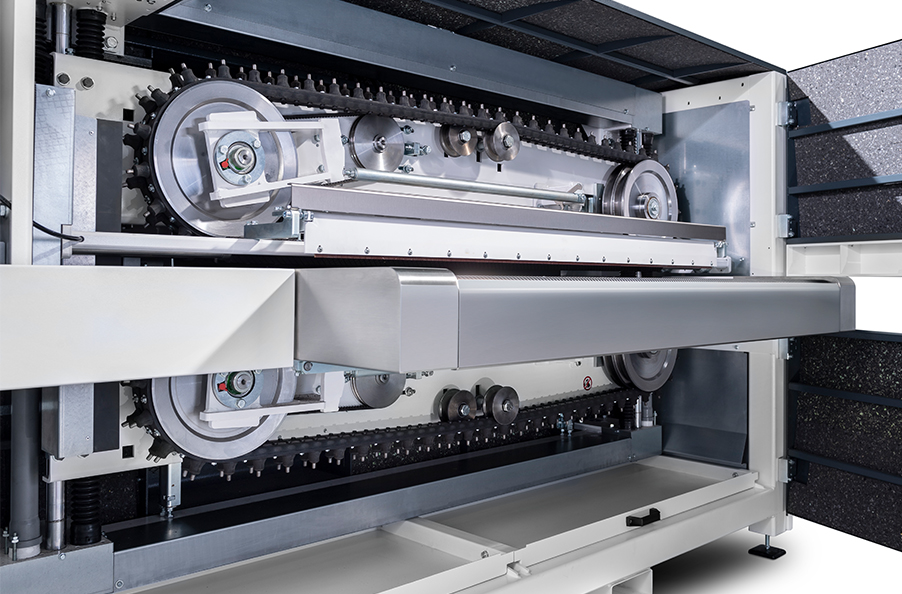

- The cross-machining principle guarantees uniform tool utilisation over the entire working width.

- Upper and lower assemblies separated can be adjusted or turned on and off electrically

- Innovative tooling and material feed system allows for optimum handling of burrs and uneven surface of pieces

- Maximum productivity while maintaining machining quality

- Improved work environment – Reduction of dust, dirt and noise

- Optionally available: Conveyor Systems; Material Handling; Robotics & Automation; Processing Tools