Produktbeskrivelse

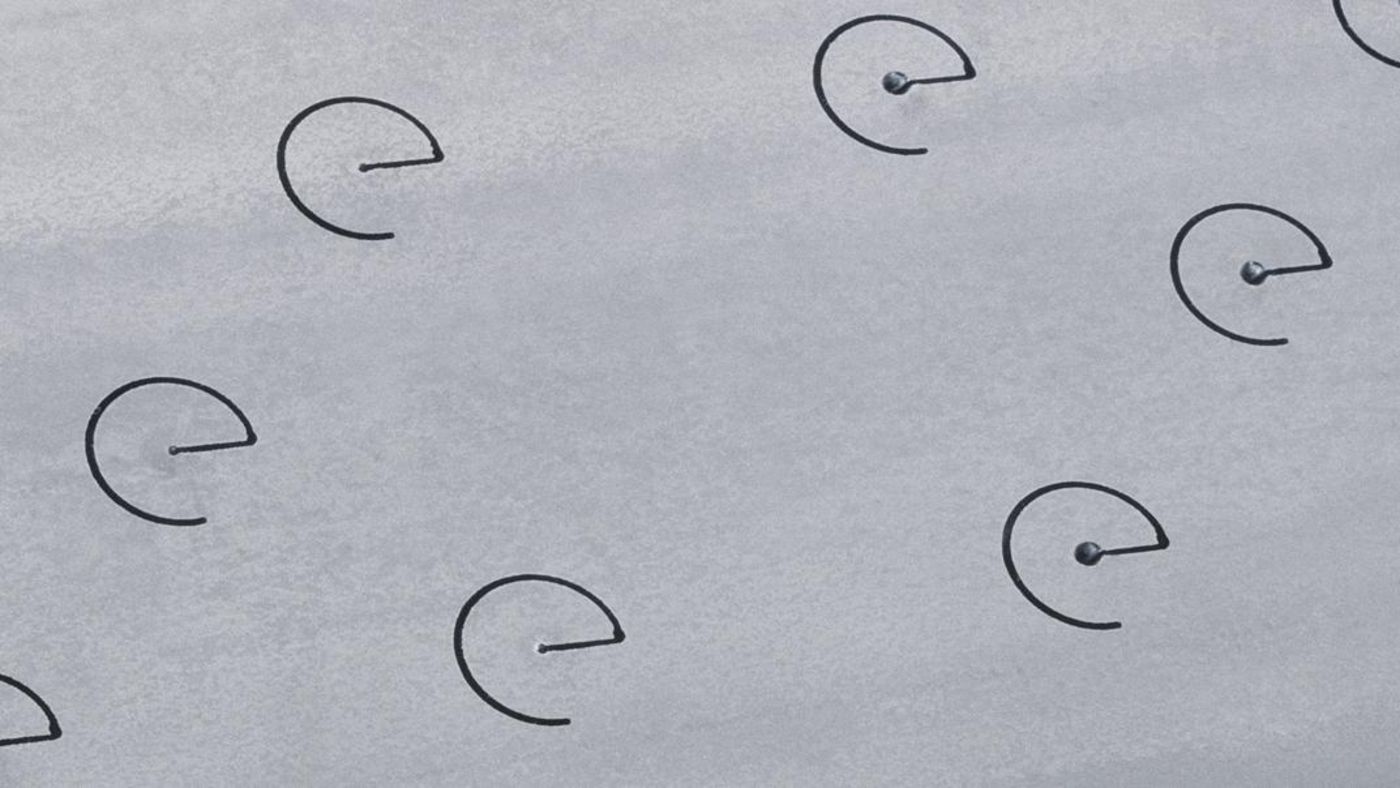

zPerfect quality

With the TruFlow CO2 laser, you can achieve perfect, micro-burr-free cutting results.

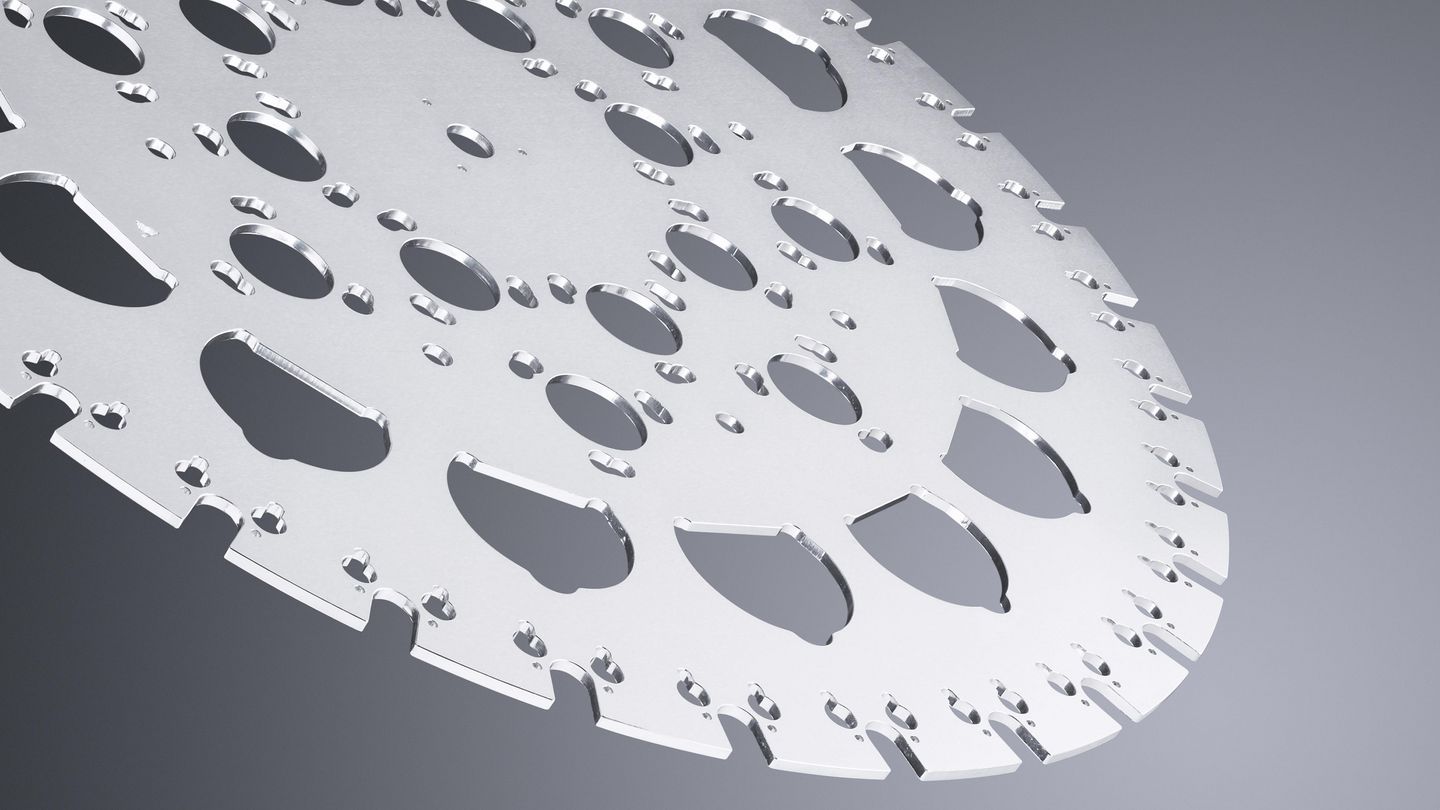

Perfect edges

Achieve extremely smooth cutting edges in stainless steel with BrightLine.

Flexible layout

You can adapt the installation completely to your requirements – transverse layout is even possible.

Processing tubes

Cut tubes directly on your flatbed laser machine with RotoLas.

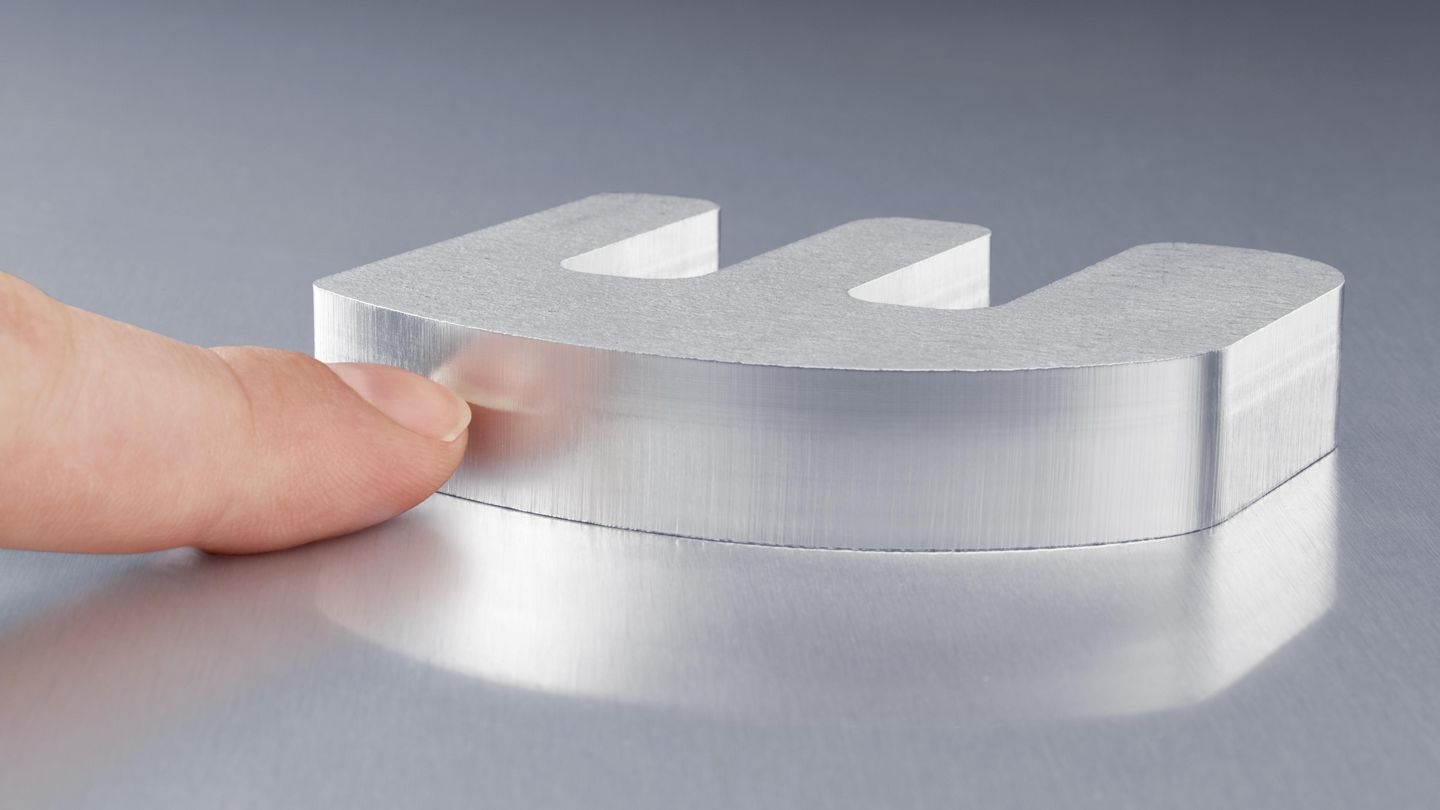

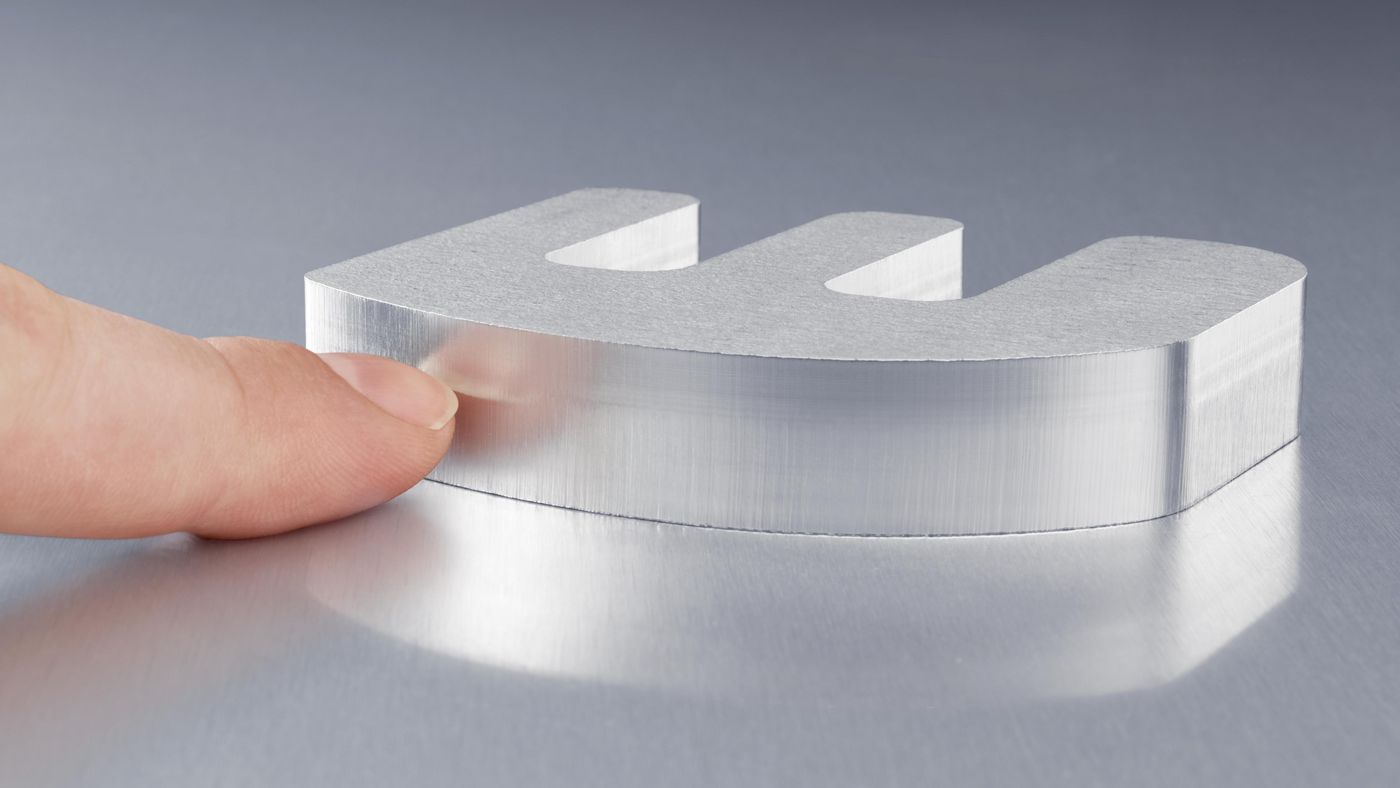

Delicately cut thick mild steel

With the CoolLine function, you can even create small contours in thick mild steel.

Utilize remainder sheets – post-produce parts easily

Using Drop&Cut, you can easily post-produce parts from remainder sheets.

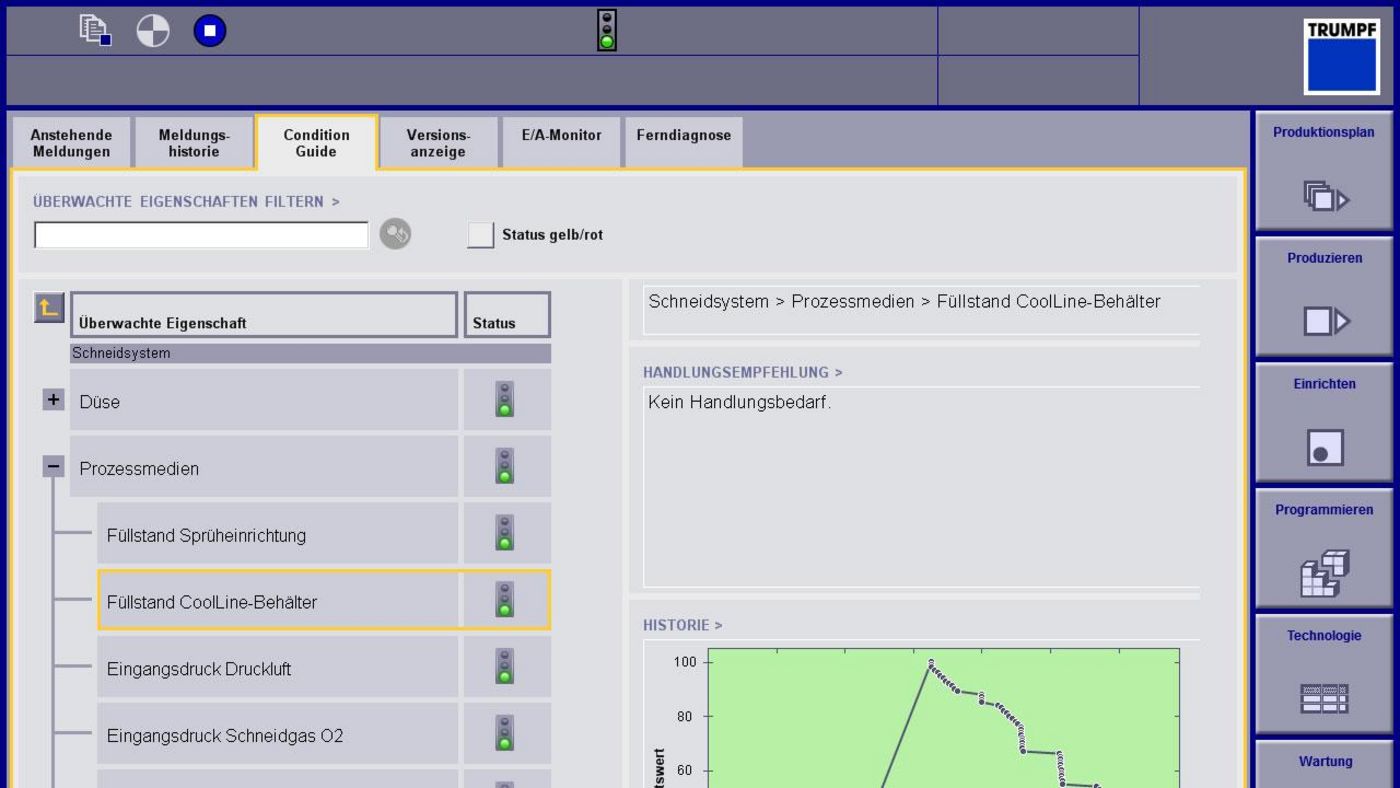

Increased machine availability

Condition Guide always monitors the condition of your machine.

Automation

Loading

Your entry into automation: The

LoadMaster enables the automatic loading of your machine with raw sheets

Loading and unloading

The compact

LiftMaster Compact loads and unloads your machine completely automatically and extremely fast. With the LiftMaster Linear Basic you have the option of multiple-machine connection

Loading and unloading / Part sorting

The automation solution,

LiftMaster, covers a broad range of functions. It loads and unloads, but is also suitable for pallet handling or part removal. The LiftMaster Sort also separates finished parts from the scrap skeleton. LiftMaster Store and LiftMaster Store Linear connect your system directly to the store. The SortMaster automatically sorts finished parts.

Auxiliary pallet operation

The

PalletMaster Tower enables flexible material handling around the clock. It combines the automatic changing of pallets with compact storage technology.

Storage system

With the storage systems of the

TruStore Series 1000 and

TruStore Series 3000 you can organize your material handling according to your requirements.