TruLaser Center 7030

Full-service machine for your laser production

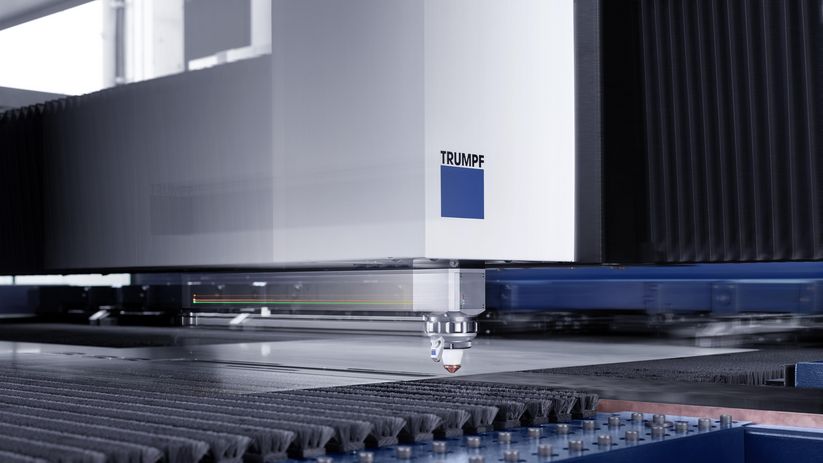

The TruLaser Center 7030 integrates all laser cutting processes into a single machine for the first time. The advantage for you: Your throughput time and processing costs will be drastically reduced. As a result, you get the optimal profitability out of your laser machining process.

Technical data

Equipment

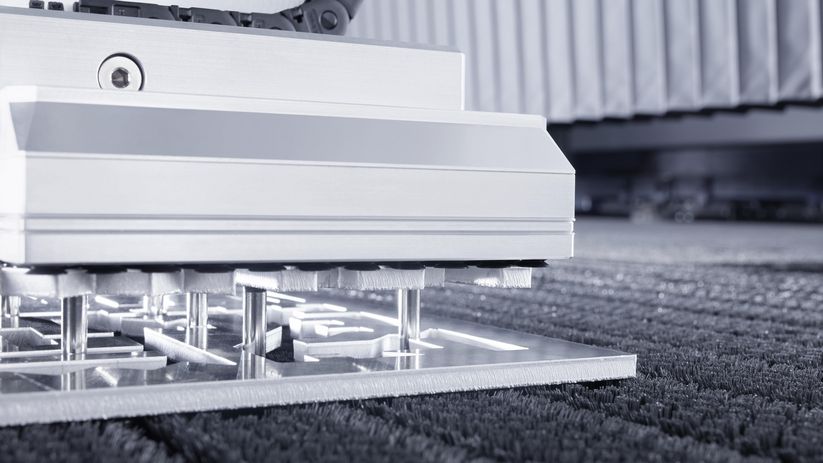

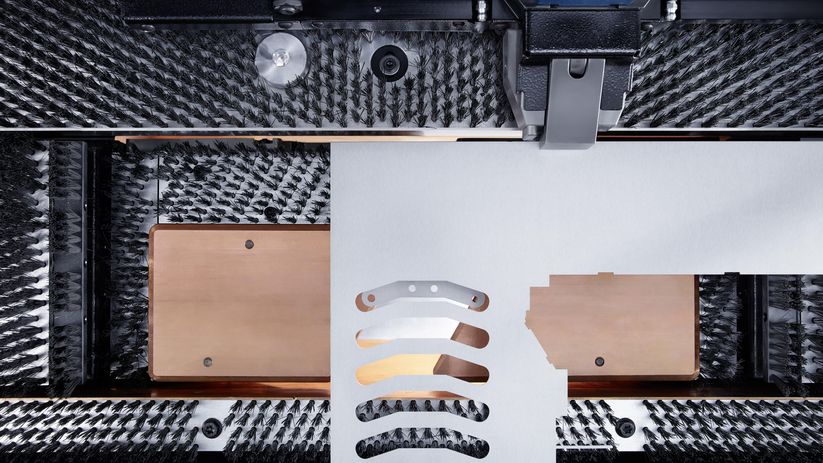

The SmartGate, along with the brush tables, prevent the tilting and unwanted welding of parts. The intelligent support moves with the cutting head and provides support for your parts during cutting. The ejector cylinder automatically finds the best point for every part geometry to push the part out through the scrap skeleton and discharge it securely.

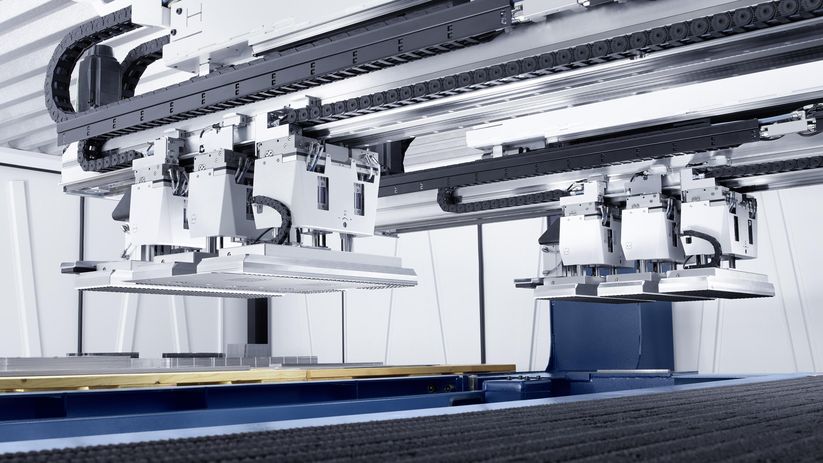

SmartLift and SortMaster Speed

The pins of the SmartLift, which can be positioned with flexibility, press the cut parts against the suction plate of the SortMaster Speed from below. At the same time, this fixes the part from above. Fixed in this way, the part is taken out of the scrap skeleton by a synchronous lift motion. This means even delicate parts are held securely and do not tilt in the kerf.

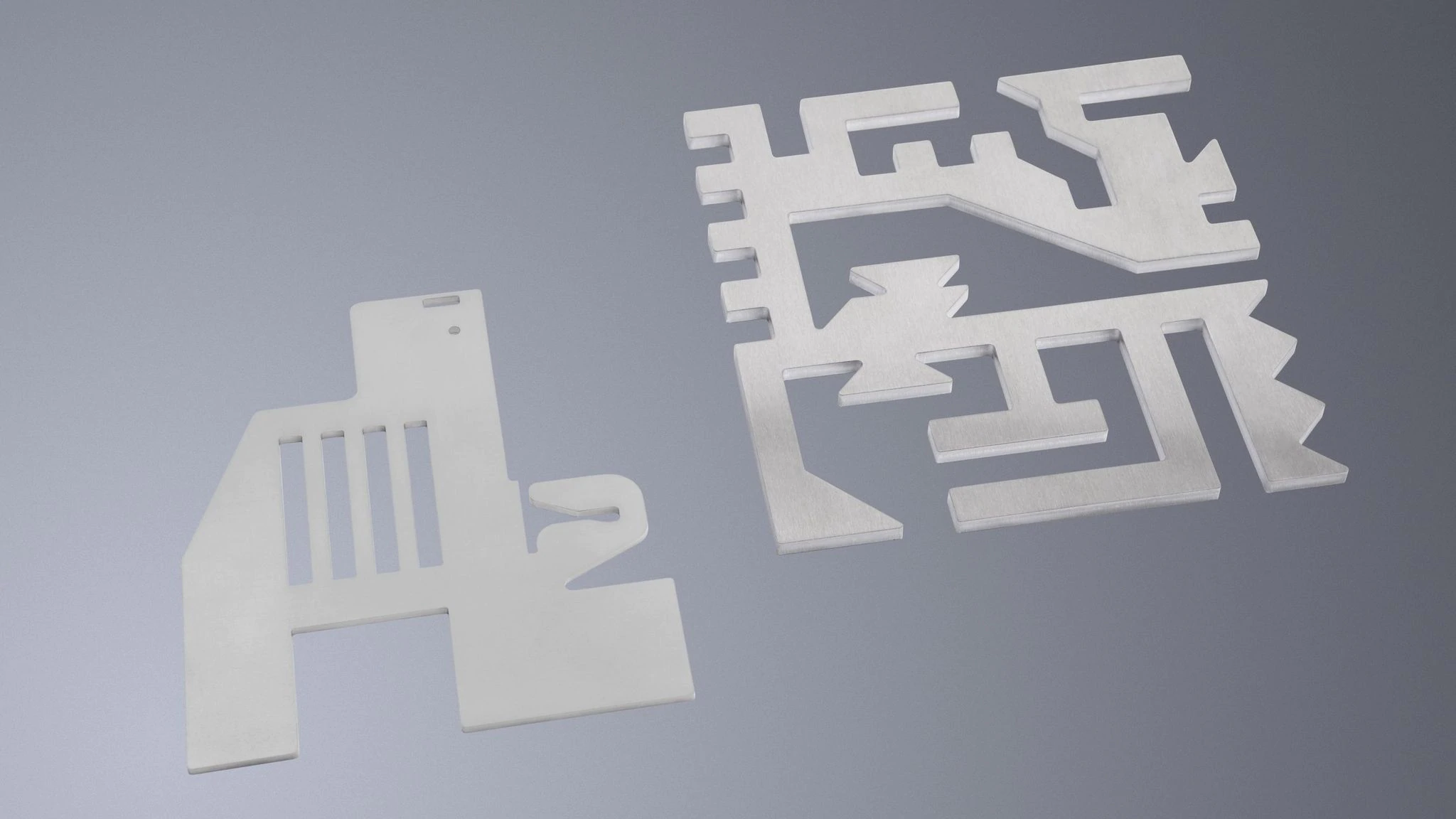

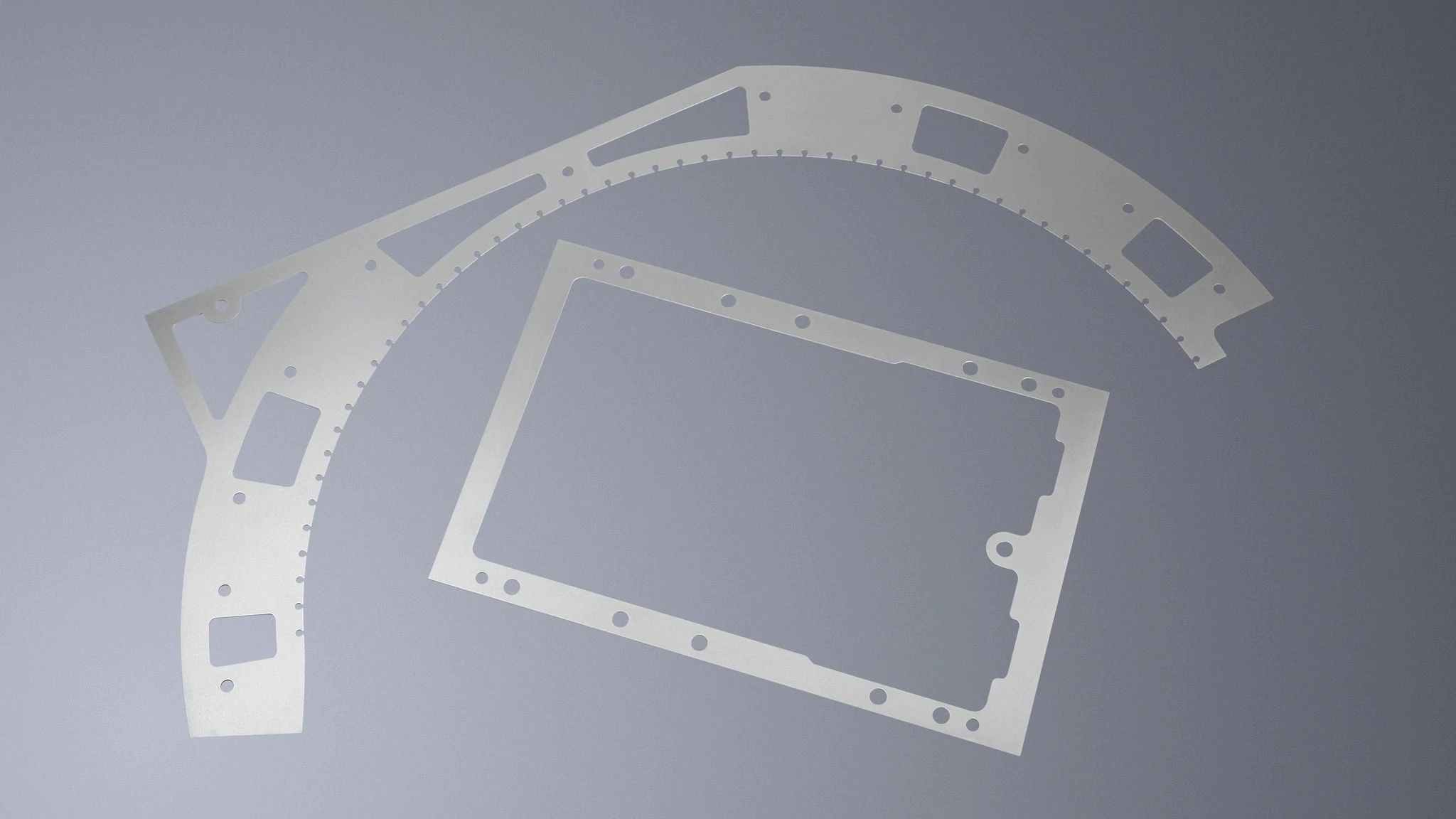

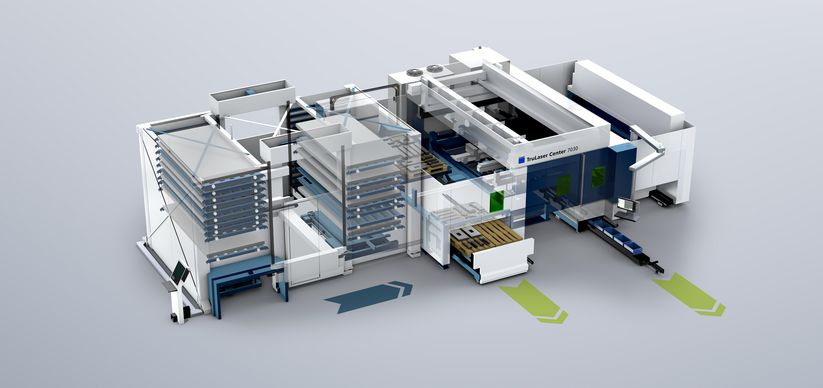

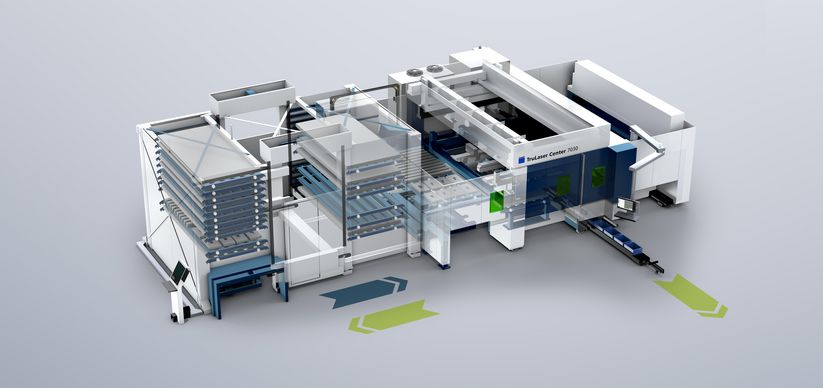

Hybrid machine concept

The movement of the sheet is superimposed by a highly dynamic additional axis on the cutting head. This means that you can cut corners and complex contours at high speeds. This strong combination means that you get the most out of the high feed rates of the solid-state laser.

SmartGate

Within seconds, the SmartGate removes small parts into up to eight containers. Slugs and scrap fall into a slag cart. Your key for maximum throughput: The removal of residual material causes minimal interruption to the cutting process – a result of the intelligent control and sensor system of the SmartGate.

SortMaster Speed

The SortMaster Speed stacks parts at lightning speed and with perfect order on up to eight pallets. As soon as the SortMaster Speed takes the part, the machine continues cutting. The part is taken to its deposit position parallel to production. Interruption to the machining process is minimal.

Programming

The TruTops Boost programming system automatically generates a suggestion for the cutting, removal, sorting, and depositing of parts. In doing so, it even takes physical conditions into consideration. For example, how the part can best be pushed out of the scrap skeleton to eliminate any chance of it tipping.

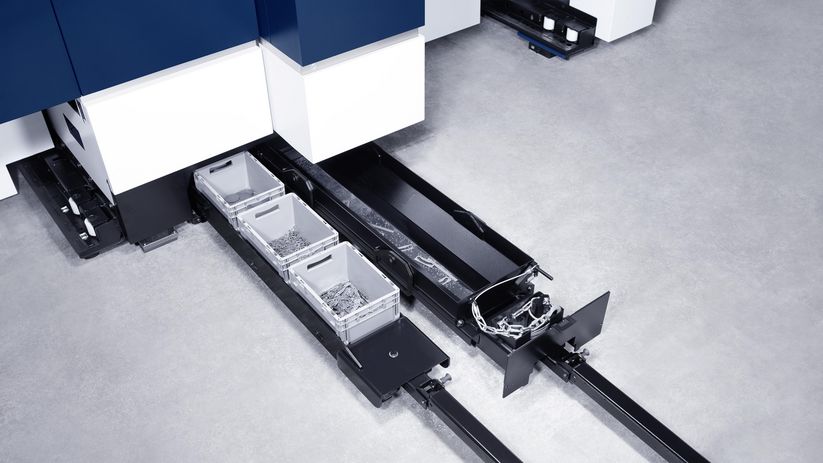

SortMaster Box Linear

A sorting flap reliably separates finished parts from scrap. The SortMaster Box Linear sorting unit distributes small parts into up to eight containers parallel to production. The containers are assigned intelligently by the software program.

Processing cell

The processing cell loads and unloads independently and announces when the operator is needed. Because of this, the operator can plan his/her work at the machine better. Waiting times, manual sorting, and rework are a thing of the past. The Touchpoint user interface also enables an intuitive dialog with the machine.

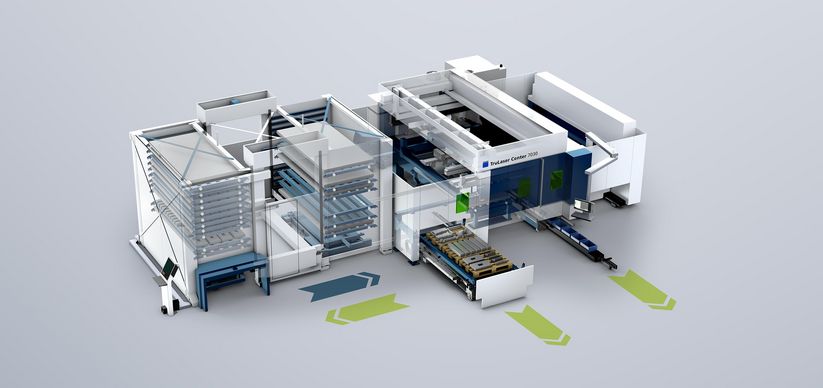

LoadMaster Center

The LoadMaster Center places the unprocessed sheet on the brush table in the clamping unit. High-performance peeling techniques separate the sheet reliably from the stack.

Automatic nozzle changer

Through program control, the automatic nozzle changer inserts the correct nozzle. The nozzle changer is located in the machine cabinet during processing, which makes it possible to set up parallel to production.

Storage connection

Large store, short distances

Front storage connection for unprocessed material

Side storage connection for unprocessed material

Side storage connection for unprocessed material and finished parts