Produktbeskrivelse

One machine, many options

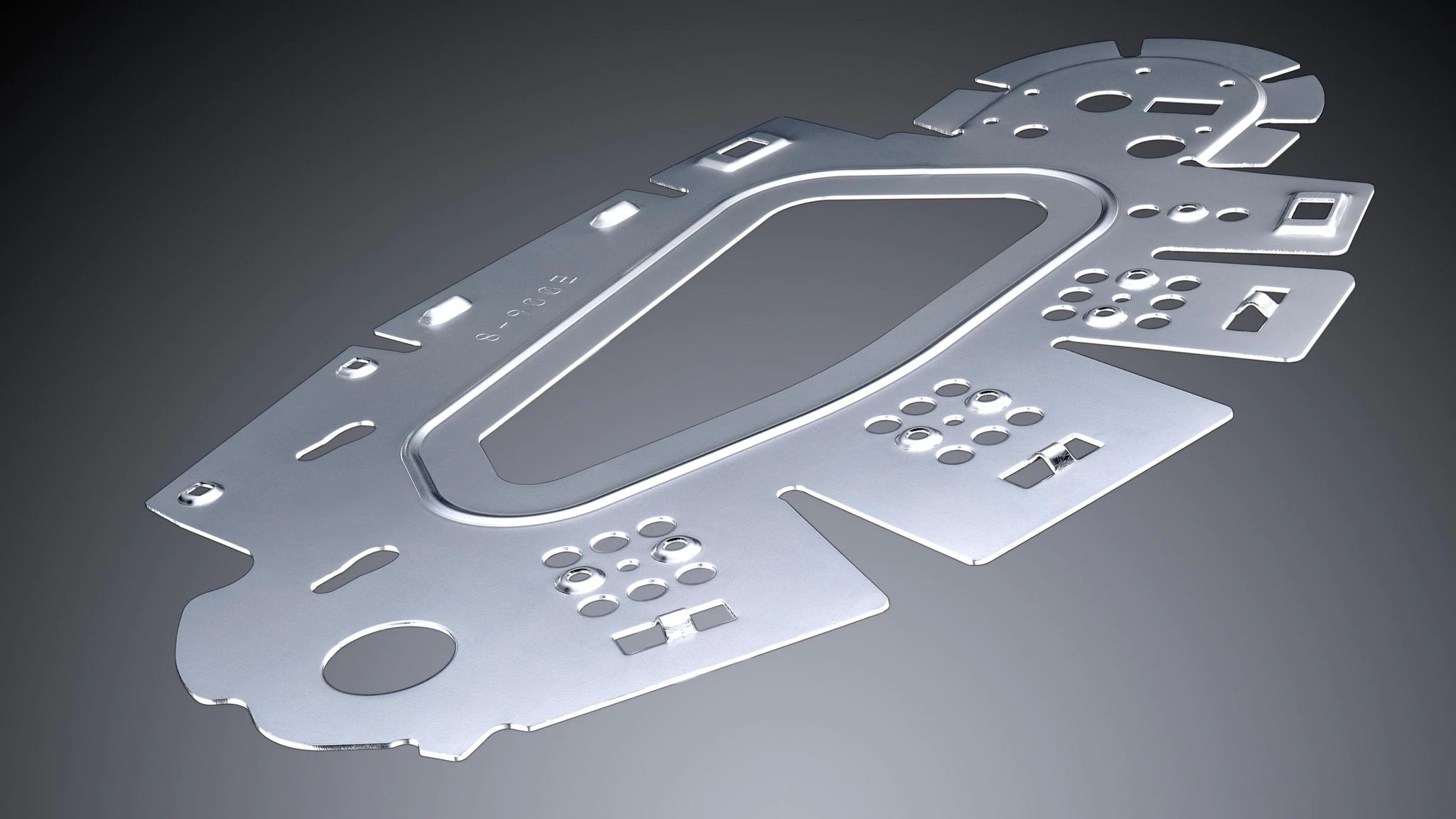

You can laser, form, punch, tap, emboss, mark, engrave and deburr with a TruMatic machine.

High-quality results

Scratch-free punching thanks to the descending die.

Clever parts handling, automatic loading and unloading

Removal and sorting solutions for small to large parts. The SheetMaster Compact loads and unloads, the SortMaster

Compact sorts finished parts.

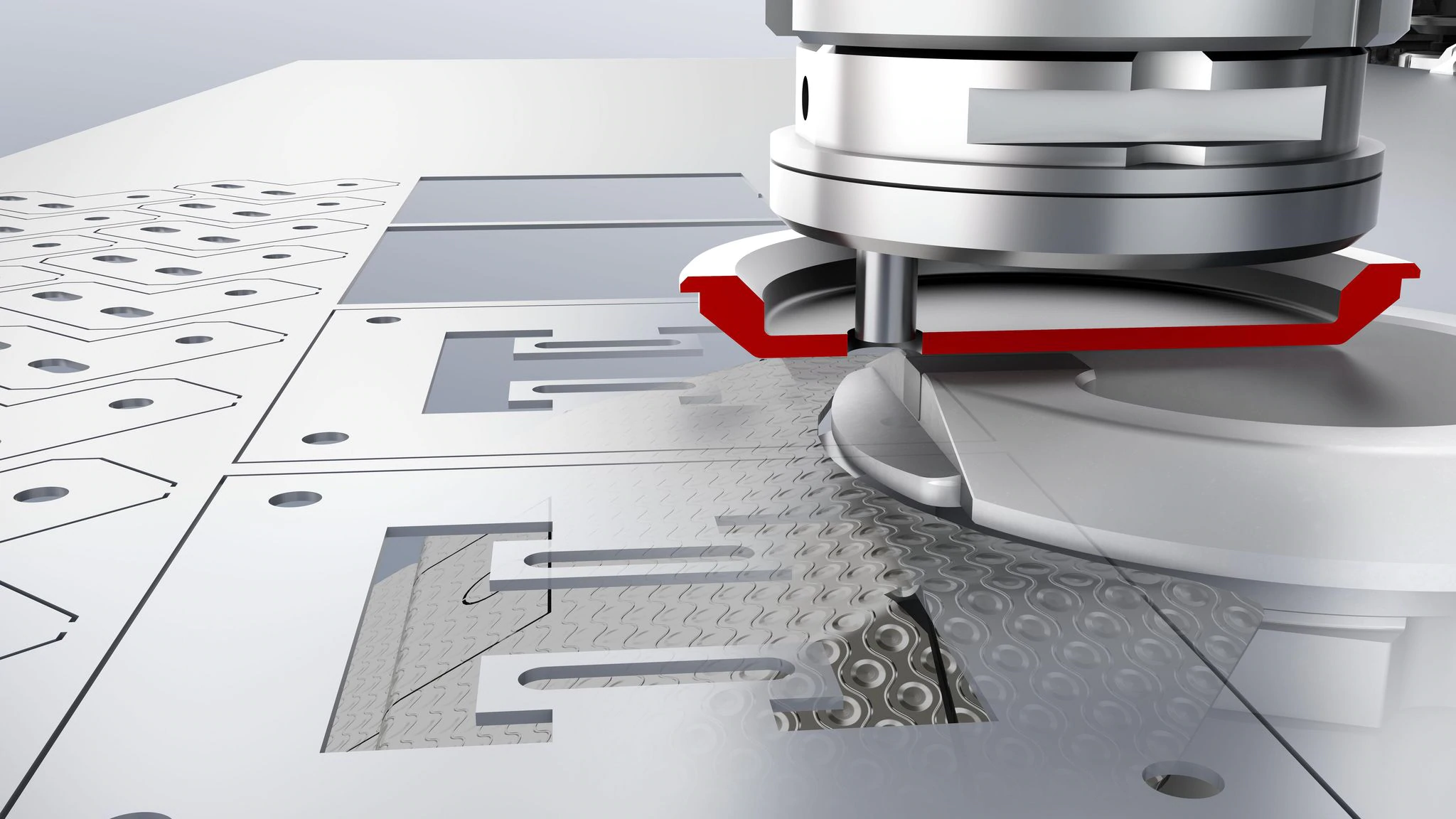

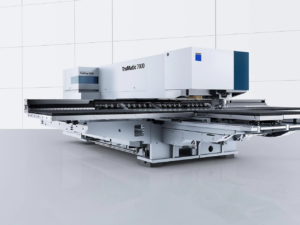

Innovative drive, compact design

The Delta Drive brings more dynamic to the machine – and saves 25% of the installation area compared to a sheetmover machine.

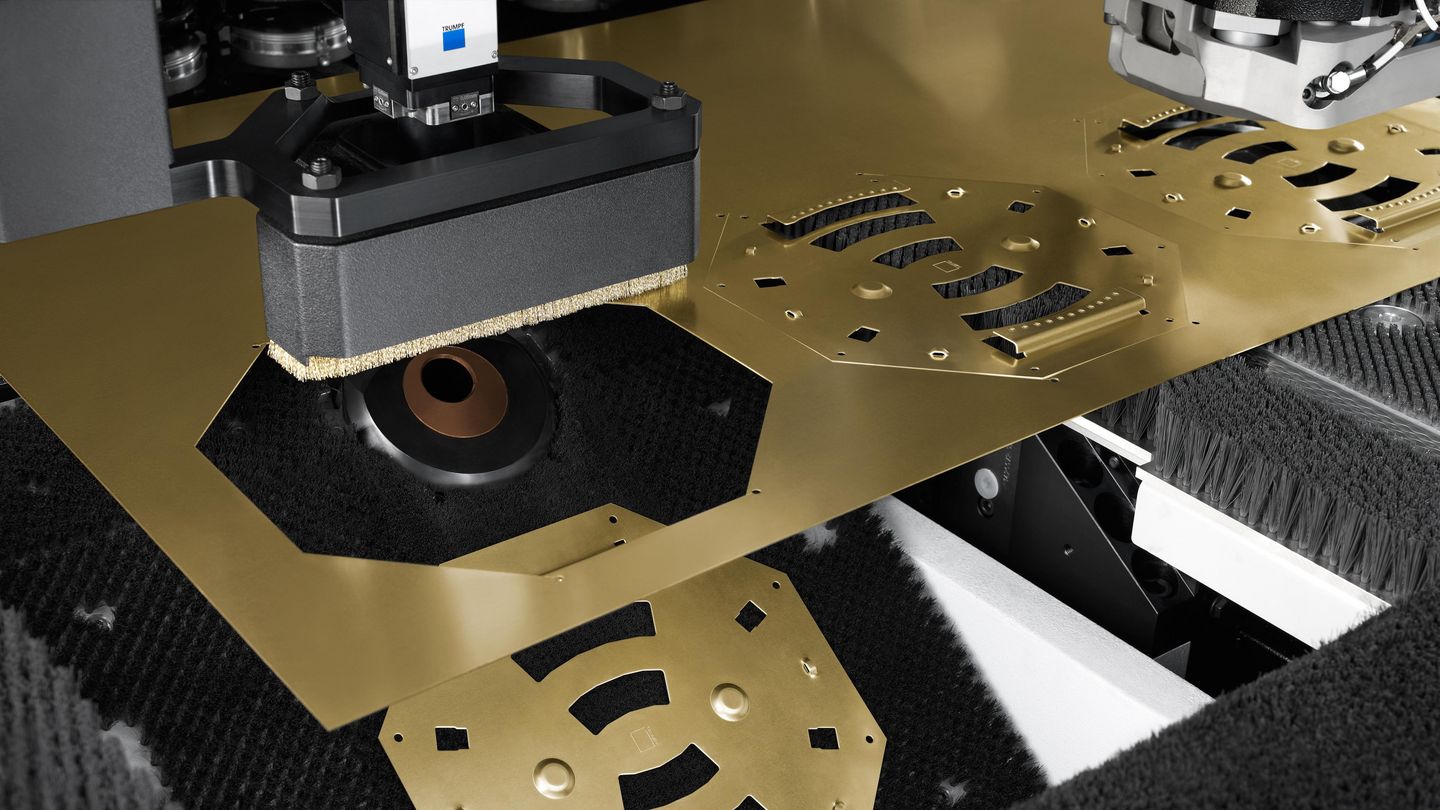

Flexible laser processing

With the robust TruDisk solid-state laser, you can achieve excellent productivity even when cutting non-ferrous metal.

Simple operation

Fewer operating steps, easy to learn – the touchpoint HMI makes it much easier to work with the machine.

Equipment

The descending die enables scratch-free punching and forming processes. If required, the die can be lowered during positioning so the sheet does not have any contact with the die – for both punching as well as higher forming dies. When forming downwards, there is no longer the risk of things getting caught.

Ball tables or brush tables

For sensitive materials, which must not have any scratches underneath, you can use brush tables combined with the descending die. Parts which are to be subsequently painted, can also be processed on the handy ball table.

When punching sheet metals, compression and tensile stresses are placed on the workpiece which can cause sheet deformation. The integrated flattening machine function and the corresponding tool make it possible to even out surface irregularities during the punching process itself.

Before a tool change, this function checks whether the sheet has actually been punched. In this way, the machine detects at an early stage when punches are broken, and can pass this information on to the operator. The smart punch monitoring function therefore avoids rejects, especially during night or weekend shifts.

The Delta Drive decouples the punch and the die and so enables new punch applications. One highlight of punch laser operation is process-reliable removal of small, laser-cut parts. The upper tool punches with a slight offset, which means that small parts do not fall through the die into the scrap container but instead slide through a part chute into waiting boxes.

Your machine automatically sorts parts up to a size of 7 x 7 in. Finished parts go through a chute into an intermediate buffer storage. There are four different boxes under the machine. The intermediate buffer storage moves to the correct box and adds the parts to this.

Parts conveyor belts

Parts that are removed via the large part removal flap can be transported into boxes via conveyor belts.

Chip conveyor

The chip conveyor can be used to automatically transport punching slugs into a container.

Touchpoint HMI

It can be very easy to program punching or punching-laser parts – machine operation becomes as intuitive as when using a tablet or smartphone with the new Touchpoint-HMI from TRUMPF. It helps you finish the part much more quickly – and even novices will quickly learn how to work with the software.

With the MobileControl app from TRUMPF you can operate and monitor your machines easily and with flexibility as the app transmits the interface of the standard control panel onto the touch screen of your tablet PC. In addition to the static control panel, you have another option for monitoring and controlling your machine.

Preparation for laser network

The laser can be equipped with an additional output for if you wish to operate the machine in a laser network. In a laser network, a TruDisk supplies several TRUMPF machines.

Software

Construct and program your laser, punching, and combined punch laser machines intelligently with TruTops Boost, your all-in-one 3D solution. Numerous automated processes save you time-consuming routine processes and the joint nesting pool saves time and material. You also always have an overview of all manufacturing orders and order-based work.

Use your machine data: the TRUMPF Machine Apps give you direct access to the world of TruConnect, TRUMPF's digital network. Analyze your data and make your production more efficient!

The extensive range of TruTops software supports you throughout the entire production process. Control your operational workflow in a simple and targeted manner, from managing your customer orders and purchasing processes to delivery of the produced parts. Through the direct coupling with the machine control, you can keep a constant eye on the status of your orders.