Produktbeskrivelse

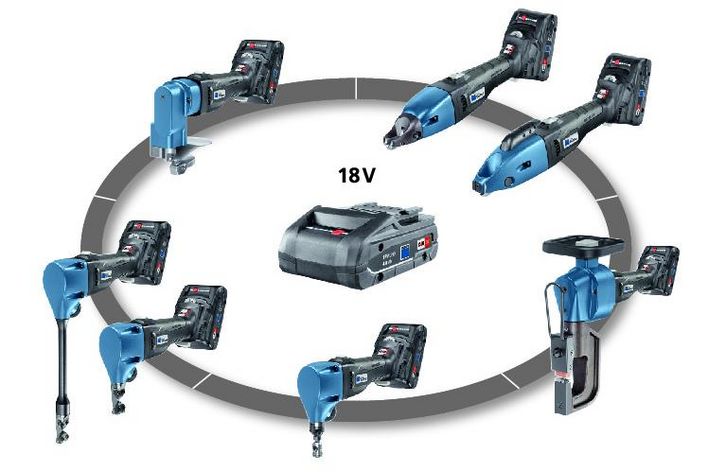

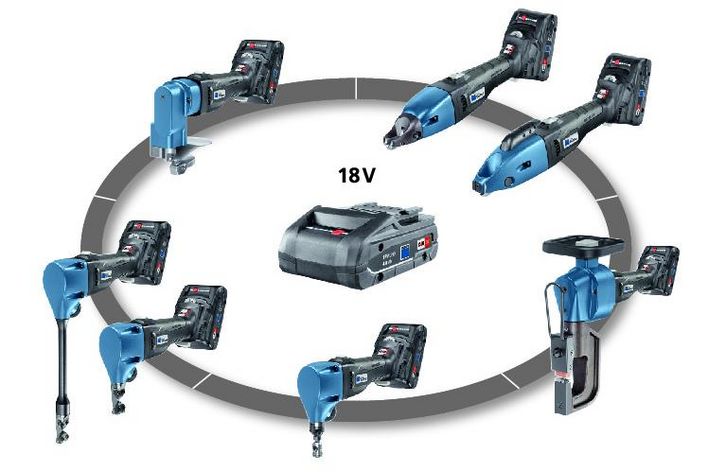

Cordless Alliance System

Cross-manufacturer rechargeable battery system for leading power tool brands. 100% compatibility in the 18-volt class.

Brushless motor

Almost unlimited service life, virtually wear-free and hardly any maintenance required. Battery performance per charge is also increased.

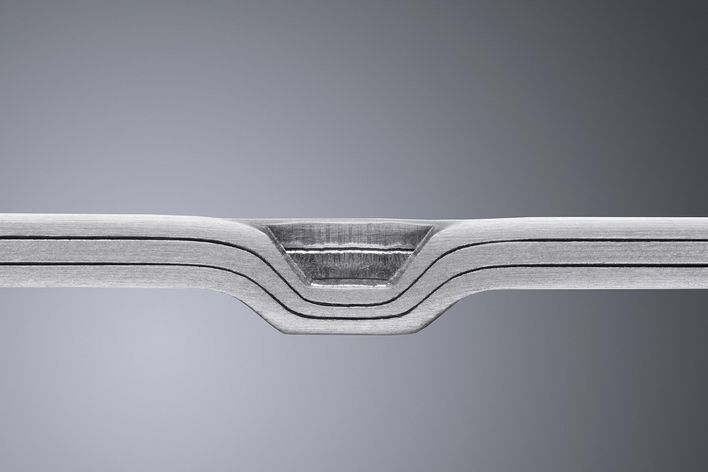

Straight to the point

The connection point is secure and resilient and the joining points are resistant to corrosion.

No fasteners

No screws or rivets are used. This saves money and simplifies handling.

Cordless Alliance System

This product is part of the Cordless Alliance System. CAS means one battery for everything, 100% compatibility for machines, rechargeable battery packs and rechargers – regardless of manufacturer. The world’s most powerful battery system with 30 years of battery expertise from Metabo. Maximum reliability, clear cost benefits and a sound investment.

Battery technology

LiHD rechargeable battery technology means more power, service life and runtime It charges reliably using process-controlled charging and discharging management. By cells being protected by minimal temperature build-up and permanent electronic single cell protection (ESCP), even when used over very long periods. The result: high-quality materials and intelligent battery management combined with brushless motors and power-head technology mean longer runtimes. The rechargeable battery pack’s outer rubber coating also provides secure and non-slip stability as well as impact protection.

Customer benefits

Power-Head Technology

The light metal gear head's ingenious design is specially adapted to the low voltage battery technology. Decoupling the motor pinion from the motor minimises energy loss and ensures even higher performance per battery charge.

Brushless motor

The powerful BL motor generates higher torques than conventional motors, requires less power and generates hardly any heat. This positively affects battery performance and means you get the maximum from every battery charge. A further advantage is the practically limitless service life of a BL motor due to the absence of carbon brushes and therefore no mechanical wear. This means almost wear-free and maintenance-free motors.

Compact and powerful

The 18V rechargeable battery tool has a lightweight design enabling fatigue-free working. The soft grip ensures safe and low-vibration working. All TRUMPF rechargeable battery tools are also available as stand-alone versions, i.e. without rechargeable batteries and charger. If you already have CAS batteries available, you then have the option to save on resources and cut costs.

Optimal working speed

You can use the speed controller to adjust the working speed to suit the individual cutting task. It is extremely efficient if you work in accordance with the predefined cutting lines or a template. It is also well-suited to frequent processing of radii and stainless steel. The electronic overload protection offers yet another notable benefit.

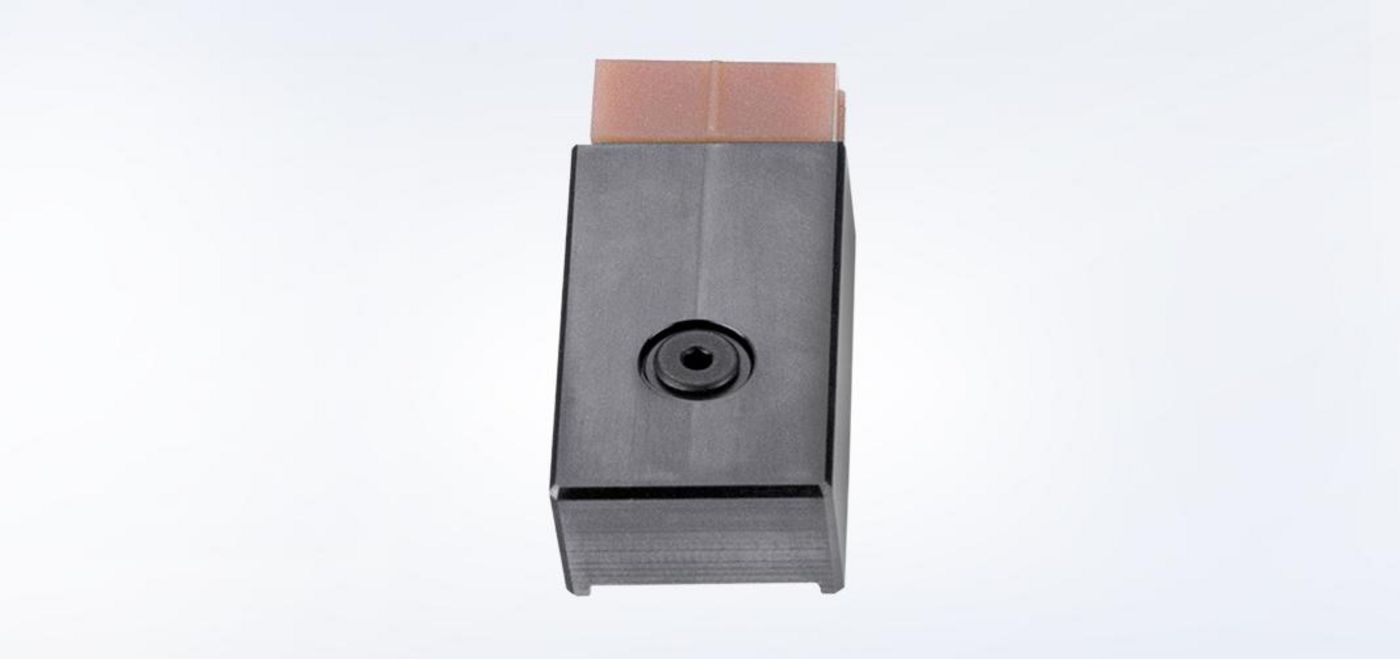

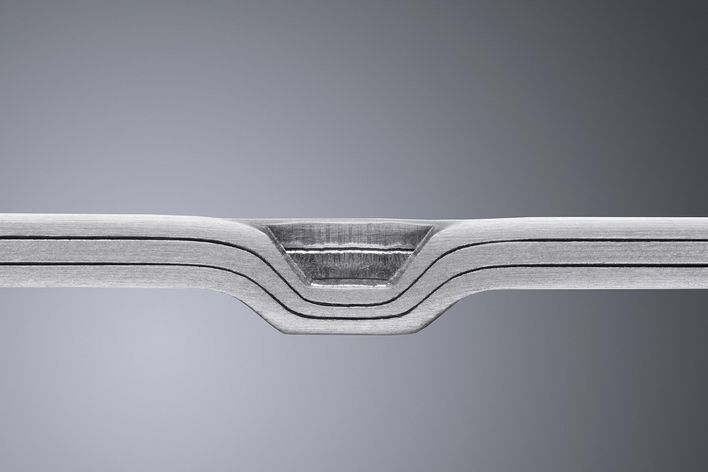

Straight to the point

With displacement joining, the sheets of metal to be joined are placed on top of each other. Then the tool cuts a strip into the sheets in a combined punching and forming operation. The top sheet is joined with the lower one with a form-fitting and corrosion-resistant connection as the materials flow into one another. The connection point solidifies and you get a permanent connection without the need for filler materials or heat.

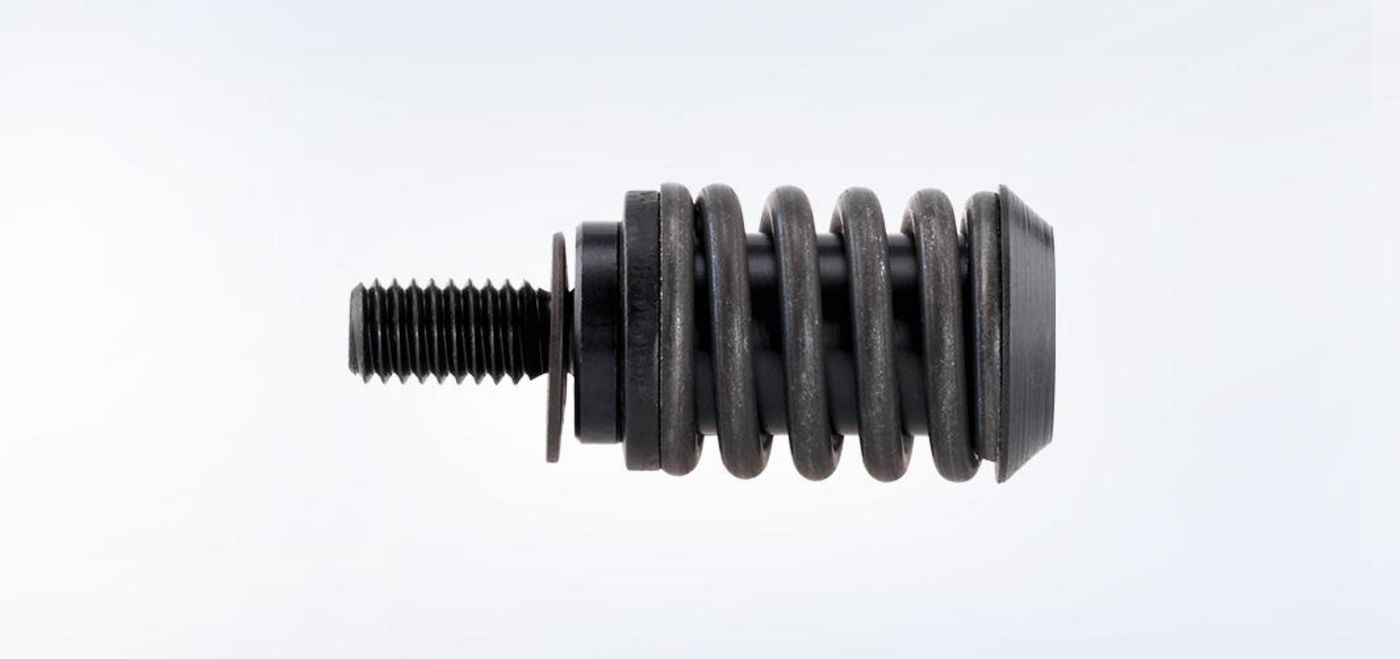

No connecting elements

The rectangular joining point appears as a shallow raised spot. This means that you have no interference contour, such as with edges for example, which you find with screws and rivets. The simple handling offers the benefit that no connecting elements need to be provided and the machine is therefore quickly ready for use. The TruTool TF 350 can also be adapted to the desired application quickly and easily. Simply choose the relevant tool.

User-friendly

The TruTool TF 350 power fastener offers an impressively compact and slim design, which makes it particularly well-suited to uses where space is limited. The geometry of the tool also has a large throat depth with a minimal interference contour. This produces flawless connections when processing ventilation ducts. Applications on tight corners and small flange widths are also no problem for the TruTool TF 350.

Perfect surface

The joining zone is exposed to neither thermal loading nor tension. The protective layer flows with the material during forming. This means that the material properties remain unchanged and free of oxidation, and the surface structure is not damaged. There is no need for preliminary work or reworking. A further benefit is that with clinching you avoid contamination of the material surface. This is perfect for coated and uncoated materials; even sheet metal with a layer of oil is ideally suited to this.